More data is being added to this page. While we do that, please visit the publication page of Prof. Wang to access the complete list of publications.

Disclaimer: The documents listed on this page are copyright-protected. By clicking on the [PDF] links below, you confirm that you or your institution have the right to access the corresponding pdf file.

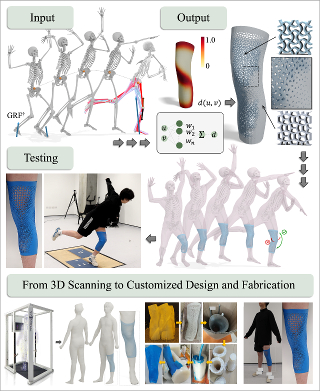

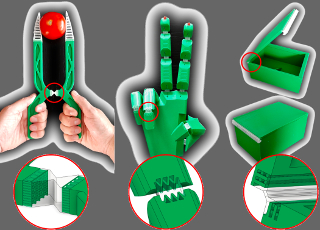

Joint injuries, and their long-term consequences, present a substantial global health burden. Wearable prophylactic braces are an attractive potential solution to reduce the incidence of joint injuries by limiting joint movements that are related to injury risk. Given human motion and ground reaction forces, we present a computational framework that enables the design of personalized braces by optimizing the distribution of microstructures and elasticity. As varied brace designs yield different reaction forces that influence kinematics and kinetics analysis outcomes, the optimization process is formulated as a differentiable end-to-end pipeline in which the design domain of microstructure distribution is parameterized onto a neural network. The optimized distribution of microstructures is obtained via a self-learning process to determine the network coefficients according to a carefully designed set of losses and the integrated biomechanical and physical analyses. Since knees and ankles are the most commonly injured joints, we demonstrate the effectiveness of our pipeline by designing, fabricating, and testing prophylactic braces for the knee and ankle to prevent potentially harmful joint movements.

Xingjian Han, Yu Jiang, Weiming Wang, Guoxin Fang, Simeon Gill, Zhiqiang Zhang, Shengfa Wang, Jun Saito, Deepak Kumar, Zhongxuan Luo, Emily Whiting, and Charlie C.L. Wang

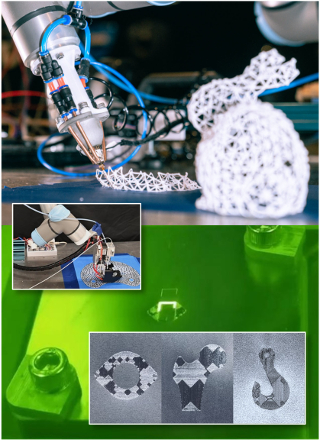

This paper presents a learning based planner for computing optimized 3D printing toolpaths on prescribed graphs, the challenges of which include the varying graph structures on different models and the large scale of nodes & edges on a graph. We adopt an on-the-fly strategy to tackle these challenges, formulating the planner as a Deep Q-Network (DQN) based optimizer to decide the next ‘best’ node to visit. We construct the state spaces by the Local Search Graph (LSG) centered at different nodes on a graph, which is encoded by a carefully designed algorithm so that LSGs in similar configurations can be identified to re-use the earlier learned DQN priors for accelerating the computation of toolpath planning. Our method can cover different 3D printing applications by defining their corresponding reward functions. Toolpath planning problems in wire-frame printing, continuous fiber printing, and metallic printing are selected to demonstrate its generality. The performance of our planner has been verified by testing the resultant toolpaths in physical experiments. By using our planner, wire-frame models with up to 4.2k struts can be successfully printed, up to 93.3% of sharp turns on continuous fiber toolpaths can be avoided, and the thermal distortion in metallic printing can be reduced by 24.9%.

Yuming Huang, Yuhu Guo, Renbo Su, Xingjian Han, Junhao Ding, Tianyu Zhang, Tao Liu, Weiming Wang, Guoxin Fang, Xu Song, Emily Whiting, and Charlie C.L. Wang

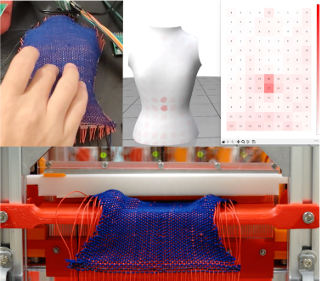

In this paper, we present a new computer-controlled weaving technology that enables the fabrication of woven structures in the shape of given 3D surfaces by using threads in non-traditional materials with high bending-stiffness, allowing for multiple applications with the resultant woven fabrics. A new weaving machine and a new manufacturing process are developed to realize the function of 3D surface weaving by the principle of short-row shaping. A computational solution is investigated to convert input 3D freeform surfaces into the corresponding weaving operations (indicated as W-code) to guide the operation of this system. A variety of examples using cotton threads, conductive threads and optical fibres are fabricated by our prototype system to demonstrate its functionality.

Yuming Huang, Yuhu Guo, Renbo Su, Xingjian Han, Junhao Ding, Tianyu Zhang, Tao Liu, Weiming Wang, Guoxin Fang, Xu Song, Emily Whiting, and Charlie C.L. Wang

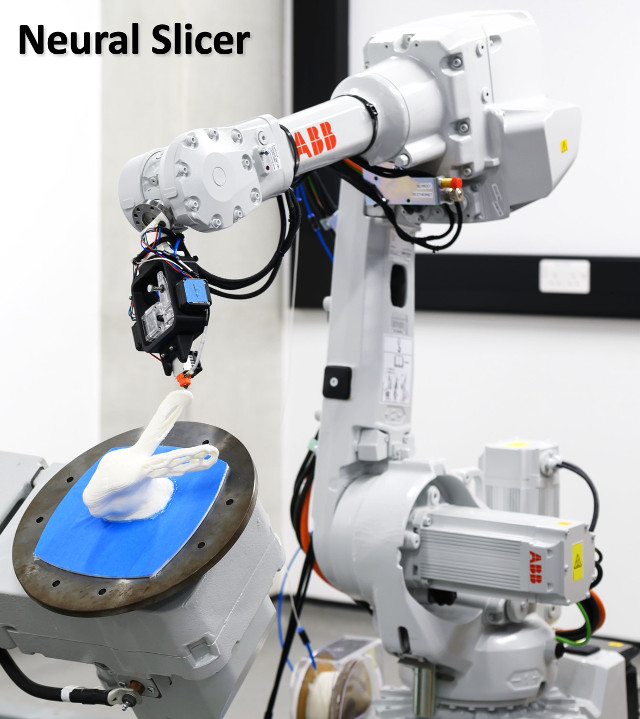

We introduce a novel neural network-based computational pipeline as a representation-agnostic slicer for multi-axis 3D printing. This advanced slicer can work on models with diverse representations and intricate topology. The approach involves employing neural networks to establish a deformation mapping, defining a scalar field in the space surrounding an input model. Isosurfaces are subsequently extracted from this field to generate curved layers for 3D printing. Creating a differentiable pipeline enables us to optimize the mapping through loss functions directly defined on the field gradients as the local printing directions. New loss functions have been introduced to meet the manufacturing objectives of support-free and strength reinforcement. Our new computation pipeline relies less on the initial values of the field and can generate slicing results with significantly improved performance.

Tao Liu, Tianyu Zhang, Yongxue Chen, Yuming Huang, and Charlie C.L. Wang

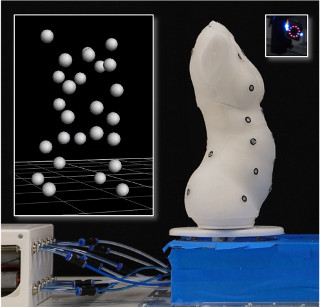

For the shape control of deformable free-form surfaces, simulation plays a crucial role in establishing the mapping between the actuation parameters and the deformed shapes. The differentiation of this forward kinematic mapping is usually employed to solve the inverse kinematic problem for determining the actuation parameters that can realize a target shape. However, the free-form surfaces obtained from simulators are always different from the physically deformed shapes due to the errors introduced by hardware and the simplification adopted in physical simulation. To fill the gap, we propose a novel deformation function based sim-to-real learning method that can map the geometric shape of a simulated model into its corresponding shape of the physical model. Unlike the existing sim-to-real learning methods that rely on completely acquired dense markers, our method accommodates sparsely distributed markers and can resiliently use all captured frames - even for those in the presence of missing markers. To demonstrate its effectiveness, our sim-to-real method has been integrated into a neural network-based computational pipeline designed to tackle the inverse kinematic problem on a pneumatically actuated deformable mannequin

Yingjun Tian, Guoxin Fang, Renbo Su, Weiming Wang, Simeon Gill, Andrew Weightman, and Charlie C.L. Wang

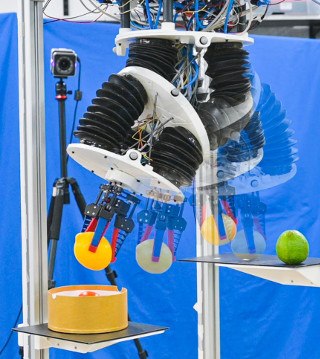

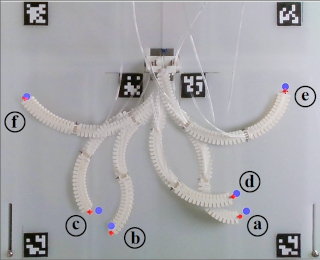

This paper presents a novel framework to realize proprioception and closed-loop control for soft manipulators. Deformations with large elongation and large bending can be precisely predicted using geometry-based sensor signals obtained from the inductive springs and the inertial measurement units (IMUs) with the help of machine learning techniques. Multiple geometric signals are fused into robust pose estimations, and a data-efficient training process is achieved after applying the strategy of sim-to-real transfer. As a result, we can achieve proprioception that is robust to the variation of external loading and has an average error of 0.7% across the workspace on a pneumatic-driven soft manipulator. The realized proprioception on soft manipulator is then contributed to building a sensor-space based algorithm for closed-loop control. A gradient descent solver is developed to drive the end-effector to achieve the required poses by iteratively computing a sequence of reference sensor signals. A conventional controller is employed in the inner loop of our algorithm to update actuators (i.e., the pressures in chambers) for approaching a reference signal in the sensor-space. The systematic function of closed-loop control has been demonstrated in tasks like path following and pick-and-place under different external loads.

Yinan Meng, Guoxin Fang, Jiong Yang, Yuhu Guo, and Charlie C.L. Wang

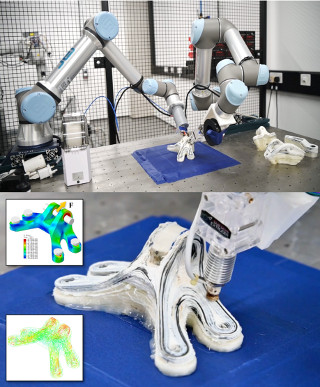

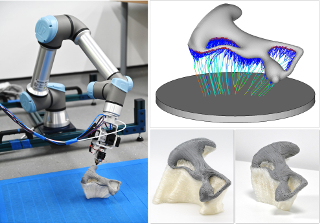

This work explores a spatial printing method to fabricate continuous fiber-reinforced thermoplastic composites (CFRTPCs), which can achieve exceptional mechanical performance. For models giving complex 3D stress distribution under loads, typical planar-layer based fiber placement usually fails to provide sufficient reinforcement due to their orientations being constrained to planes. The effectiveness of fiber reinforcement could be maximized by using multi-axis additive manufacturing (MAAM) to better control the orientation of continuous fibers in 3D-printed composites. Here, we propose a computational approach to generate 3D toolpaths that satisfy two major reinforcement objectives-1) following the maximal stress directions in critical regions and 2) connecting multiple load-bearing regions by continuous fibers. Principal stress lines are first extracted in an input solid model to identify critical regions. Curved layers aligned with maximal stresses in these critical regions are generated by computing an optimized scalar field and extracting its iso-surfaces. Then, topological analysis and operations are applied to each curved layer to generate a computational domain that preserves fiber continuity between load-bearing regions. Lastly, continuous fiber toolpaths aligned with maximal stresses are generated on each surface layer by computing an optimized scalar field and extracting its iso-curves. A hardware system with dual robotic arms is employed to conduct the physical MAAM tasks depositing polymer or fiber reinforced polymer composite materials by applying a force normal to the extrusion plane to aid consolidation. When comparing to planar-layer based printing results in tension, up to 644% failure load and 240% stiffness are observed on shapes fabricated by our spatial printing method.

Guoxin Fang, Tianyu Zhang, Yuming Huang, Zhizhou Zhang, Kunal Masania, and Charlie C.L. Wang

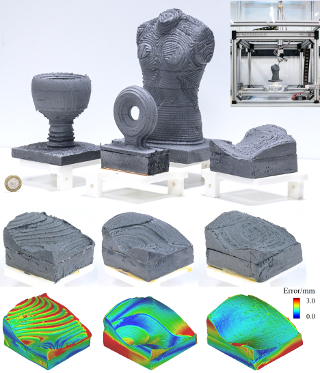

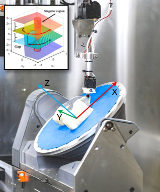

This paper presents an easy-to-control volume peeling method for multi-axis machining based on the computation taken on vector fields. The current scalar field based methods are not flexible and the vector-field based methods do not guarantee the satisfaction of the constraints in the final results. We first conduct an optimization formulation to compute an initial vector field that is well aligned with those anchor vectors specified by users according to different manufacturing requirements. The vector field is further optimized to be an irrotational field so that it can be completely realized by a scalar field’s gradients. Iso-surfaces of the scalar field will be employed as the layers of working surfaces for multi-axis volume peeling in the rough machining. Algorithms are also developed to remove and process singularities of the fields. Our method has been tested on a variety of models and verified by physical experimental machining.

Neelotpal Dutta, Tianyu Zhang, Guoxin Fang, Ismail E. Yigit, and Charlie C.L. Wang

ASME CIE Conference 2023 Best Paper Award

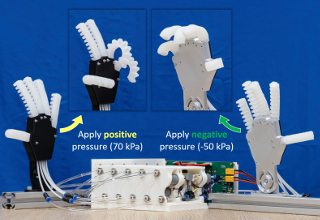

This paper presents a compact system, OpenPneu, to support the pneumatic actuation for multi-chambers on soft robots. Micro-pumps are employed in the system to generate airflow and therefore no extra input as compressed air is needed. Our system conducts modular design to provide good scalability, which has been demonstrated on a prototype with ten air channels. Each air channel of OpenPneu is equipped with both the inflation and the deflation functions to provide a full range pressure supply from positive to negative with a maximal flow rate at 1.7 L/min. High precision closed-loop control of pressures has been built into our system to achieve stable and efficient dynamic performance in actuation. An open-source control interface and API in Python are provided. We also demonstrate the functionality of OpenPneu on three soft robotic systems with up to 10 chambers.

Yingjun Tian, Renbo Su, Xilong Wang, Nur Banu Altin, Guoxin Fang, and Charlie C.L. Wang

Robot-assisted 3D printing has drawn a lot of attention by its capability to fabricate curved layers that are optimized according to different objectives. However, the support generation algorithm based on a fixed printing direction for planar layers cannot be directly applied for curved layers as the orientation of material accumulation is dynamically varied. In this paper, we propose a skeleton-based support generation method for robot-assisted 3D printing with curved layers. The support is represented as an implicit solid so that the problems of numerical robustness can be effectively avoided. The effectiveness of our algorithm is verified on a dual-material printing platform that consists of a robotic arm and a newly designed dual-material extruder. Experiments have been successfully conducted on our system to fabricate a variety of freeform models.

Tianyu Zhang, Yuming Huang, Piotr Kukulski, Neelotpal Dutta, Guoxin Fang, and Charlie C.L. Wang

This paper presents an algorithm to compute optimized toolpaths to print thin-walled cellular structures with continuous carbon fiber. The input cellular structure is usually represented by a graph G, and the requirements to ensure high quality manufacturing include the coverage, continuity and sharp-turning prevention of fiber deposition. To satisfy these requirements, we develop a new algorithm to search a continuous path on G’s dual graph, the corresponding path on which G minimizes the total energy of tuning angles and can visit all edges of G at least once and at most twice. With the help of a post-processing algorithm, a path determined on the dual graph can be converted into an overlap-reduced toolpath for printing continuous carbon fiber. Physical tests were conducted to demonstrate the advantage of printing paths generated by our algorithm. Up to 46% enhancement on the breaking force is observed during the tensile tests when using slightly less fibers.

Yuming Huang, Guoxin Fang, Tianyu Zhang, and Charlie C.L. Wang

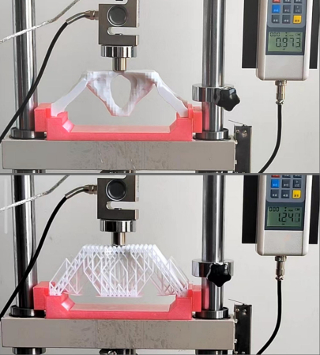

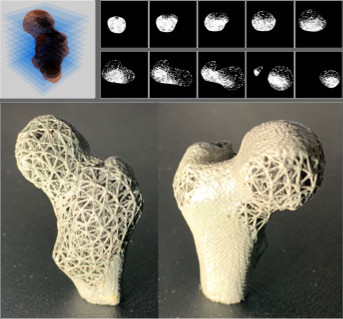

This paper presents a method to generate self-supporting lattice structures in a Topology Optimization (TO) framework. Our method is composed of two phases, which are the TO-based subdivision and the TO-based simplification. Starting from a lattice structure with self-supporting lattice unit cells in a coarse resolution, a subdivision method is proposed to adaptively generate the lattice structure based on the density-based topology optimization framework. The subdivision operators are well-designed to preserve self-supporting property on struts, and a filtering approach is proposed to avoid overhanging nodes. To remove redundant struts on the lattice structures generated by subdivision, a simplification method is developed to satisfy the required volume while a self-supporting constraint is incorporated to ensure the manufacturability of the resultant structures. Our method has been tested on both 2D and 3D examples. Experimental tests demonstrate that our method can effectively generate self-supporting lattice structures with stronger mechanical strength.

Weiming Wang, Dongwei Feng, Li Yang, Shan Li, and Charlie C.L. Wang

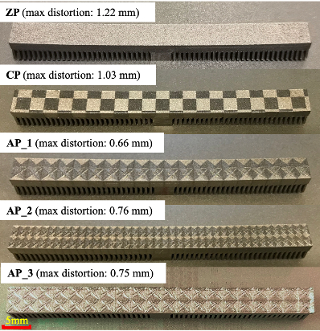

Laser powder bed fusion (LPBF) is one of the most commonly used metal additive manufacturing technologies due to its advantages in fabricating complex structures. However, traditional scan patterns often cause large distortion due to residual stresses induced during the fabrication process. In this paper, we propose novel adaptive toolpath generation algorithms based on in-situ minimizing thermal gradients so that can reduce the part distortion. The objective function of temperature fields is determined by numerical simulation both considering time and distance. Two constraints including collision-free and smoothing constraints are also incorporated during the toolpath patterns generation process. In addition, to improve the efficiency of adaptive toolpath generation algorithms for large or complex structures, island-based strategy is developed and combined with the adaptive toolpath generation algorithms. Results show that the distortion of our proposed algorithms could reduce about 46% compared with that of the zigzag patterns and reduce about 36% compared with that of the traditional chessboard-based patterns.

Mian Qin, Shuo Qu, Junhao Ding, Xu Song, Shiming Gao, Charlie C.L. Wang, Wei-Hsin Liao

Multi-axis motion introduces more degrees of freedom into the process of 3D printing to enable different objectives of fabrication by accumulating materials layers upon curved layers. An existing challenge is how to effectively generate the curved layers satisfying multiple objectives simultaneously. This paper presents a general slicing framework for achieving multiple fabrication objectives including support free, strength reinforcement and surface quality. These objectives are formulated as local printing directions varied in the volume of a solid, which are achieved by computing the rotation-driven deformation for the input model. The height field of a deformed model is mapped into a scalar field on its original shape, the isosurfaces of which give the curved layers of multi-axis 3D printing. The deformation can be effectively optimized with the help of quaternion fields to achieve the fabrication objectives. The effectiveness of our method has been verified on a variety of models.

Tianyu Zhang, Guoxin Fang, Yuming Huang, Neelotpal Dutta, Sylvain Lefebvre, Zekai Murat Kilic, and Charlie C.L. Wang

ACM SIGGRPAH Asia 2022 Best Technical Paper Award

This paper presents an efficient learning-based method to solve the inverse kinematic (IK) problem on soft robots with highly non-linear deformation. The major challenge of efficiently computing IK for such robots is due to the lack of analytical formulation for either forward or inverse kinematics. To address this challenge, we employ neural networks to learn both the mapping function of forward kinematics and also the Jacobian of this function. As a result, Jacobian-based iteration can be applied to solve the IK problem. A sim-to-real training transfer strategy is conducted to make this approach more practical. We first generate a large number of samples in a simulation environment for learning both the kinematic and the Jacobian networks of a soft robot design. Thereafter, a sim-to-real layer of differentiable neurons is employed to map the results of simulation to the physical hardware, where this sim-to-real layer can be learned from a very limited number of training samples generated on the hardware. The effectiveness of our approach has been verified on pneumatic-driven soft robots for path following and interactive positioning.

Guoxin Fang, Yingjun Tian, Zhi-Xin Yang, Jo M.P. Geraedts, and Charlie C.L. Wang

Despite the recent advances in artificial tissue and organ engineering, how to generate large size viable and functional complex organs still remains as a grand challenge for regenerative medicine. Three-dimensional bioprinting has demonstrated its advantages as one of the major methods in fabricating simple tissues, yet it still faces difficulties to generate vasculatures and preserve somatic cell functions in complex organ production. Here, we overcome the limitations of conventional bioprinting systems by converting a six degree-of-freedom robotic arm into a bioprinter, therefore enables cell printing on 3D complex-shaped vascular scaffolds from all directions. We also developed an oil bath-based cell printing method to better preserve cell natural functions after printing. Together with a self-designed bioreactor and a repeated print-and-culture strategy, our bioprinting system is capable to generate vascularized, contractible, and long-term survived cardiac tissues. Such bioprinting strategy mimics the in vivo organ development process and presents a promising solution for in vitro fabrication of complex organs.

Zeyu Zhang, Chenming Wu, Chengkai Dai, Qingqing Shi, Guoxin Fang, Dongfang Xie, Yong-Jin Liu, Charlie C.L. Wang, and Xiu-Jie Wang

MedTech Award in 3D Pioneers Challenge, May 2022

In this paper, we presented a data-driven framework to optimize the out-of-plane stiffness for soft grippers to achieve mechanical properties as hard-to-twist and easy-to-bend. The effectiveness of this method is demonstrated in the design of a soft pneumatic bending actuator (SPBA). First, a new objective function is defined to quantitatively evaluate the out-of-plane stiffness as well as the bending performance. Then, sensitivity analysis is conducted on the parametric model of an SPBA design to determine the optimized design parameters with the help of Finite Element Analysis (FEA). To enable the computation of numerical optimization, a data-driven approach is employed to learn a cost function that directly represents the out-of-plane stiffness as a differentiable function of the design variables. A gradient-based method is used to maximize the out-of-plane stiffness of the SPBA while ensuring specific bending performance. The effectiveness of our method has been demonstrated in physical experiments taken on 3D-printed grippers.

Renbo Su, Yingjun Tian, Mingwei Du, and Charlie C.L. Wang

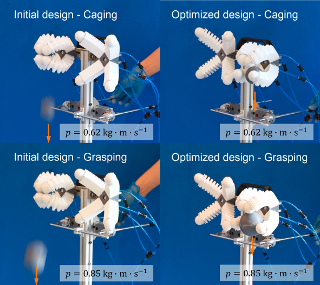

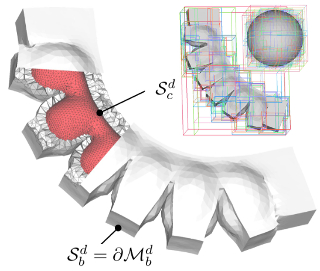

Soft robots are able to safely interact with environments because of their mechanical compliance. Self-collision is also employed in the modern design of soft robots to enhance their performance in different tasks. However, developing an efficient and reliable simulator which can handle the collision response well, is still a challenging task in the research of soft robotics. This paper presents a collision-aware simulator based on geometric optimization, in which we develop a highly efficient and realistic collision checking / response model incorporating a hyperelastic material property. Both actuated deformation and collision response for soft robots are formulated as geometry-based objectives. The collision-free body of a soft robot can be obtained by minimizing the geometry-based objective function. Different from the FEA-based physical simulation, the proposed pipeline performs a much lower computational cost. Moreover, adaptive remeshing is applied to achieve the improvement of the convergence when dealing with soft robots having large volume variations. Experimental tests are conducted on different soft robots to verify the performance of our approach.

Guoxin Fang, Yingjun Tian, Andrew Weightman, and Charlie C.L. Wang

This paper presents a novel soft robotic system for a deformable mannequin that can be employed to physically realize the 3D geometry of different human bodies. The soft membrane on a mannequin is deformed by inflating several curved chambers using pneumatic actuation. Controlling the freeform surface of a soft membrane by adjusting the pneumatic actuation in different chambers is challenging as the membrane’s shape is commonly determined by interaction between all chambers. Using vision feedback provided by a structured-light based 3D scanner, we developed an efficient algorithm to compute the optimized actuation of all chambers which could drive the soft membrane to deform into the best approximation of different target shapes. Our algorithm converges quickly by including the step of pose estimation in the loop of optimization, and the time-consuming step for evaluating derivatives on the deformable membrane is avoided by using the Broyden update when possible. The effectiveness of our soft robotic mannequin with controlled deformation has been verified in experiments.

Yingjun Tian, Guoxin Fang, Justas Petrulis, Andrew Weightman, and Charlie C.L. Wang

We propose a simple and effective 3D lattice consisting of interlaced horizontal beams in vertically alternating directions which interlock topologically- the interlaced topologically interlocking lattice (ITIL). It ensures continuous extrusion and ensures an interlock even for highly flexible materials. We develop analytical models for optimizing the ultimate tensile strength of the ITIL lattice in two different orientations relative to the interface-straight and diagonal. The analytical models are applied to polypropylene (PP) and polylactic acid (PLA) and verified by finite elements method (FEM) simulations and physical tensile experiments. In the diagonal orientation ITIL can obtain 82% of the theoretical upper bound of 8.6MPa. ITIL seems to perform comparably to dovetail interlocking designs, while it lends itself to application to non-vertical interfaces. Optimizing the lattice for non-vertical interfaces, however, remains future work.

Tim Kuipers, Renbo Su, Jun Wu, and Charlie C.L. Wang

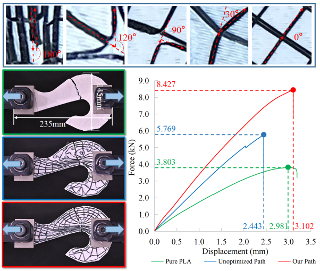

We present a field-based method of toolpath generation for 3D printing continuous fibre reinforced thermoplastic composites. Our method employs the strong anisotropic material property of continuous fibres by generating toolpaths along the directions of tensile stresses in the critical regions. Moreover, the density of toolpath distribution is controlled in an adaptive way proportionally to the values of stresses. Specifically, a vector field is generated from the stress tensors under given loads and processed to have better compatibility between neighboring vectors. An optimal scalar field is computed later by making its gradients approximate the vector field. After that, isocurves of the scalar field are extracted to generate the toolpaths for continuous fibre reinforcement, which are also integrated with the boundary conformal toolpaths in user selected regions. The performance of our method has been verified on a variety of models in different loading conditions. Experimental tests are conducted on specimens by 3D printing continuous carbon fibres (CCF) in a polylactic acid (PLA) matrix. Compared to reinforcement by load-independent toolpaths, the specimens fabricated by our method show up to 71.4% improvement on the mechanical strength in physical tests when using the same (or even slightly smaller) amount of continuous fibres.

Xiangjia Chen, Guoxin Fang, Wei-Hsin Liao, and Charlie C.L. Wang

Lattice structures have been widely used in various applications of additive manufacturing due to their superior physical properties. If modeled by triangular meshes, a lattice structure with a huge number of struts would consume massive memory, hindering their use in large-scale applications. To address this issue, we propose a memory-efficient method for modeling and slicing adaptive lattice structures. A lattice structure is represented by a weighted graph where edge weights store the struts’ radii. During slicing, its solid model is locally evaluated through convolution surfaces in a streaming manner, requiring only limited memory to generate fabrication toolpaths. Convolution surfaces also ensure natural blending at strut intersections, preventing stress concentration. Additionally, we present a computational framework for optimizing support structures and adapting lattice structures with prescribed density distributions. Our methods have been validated through case studies with up to 100M struts, demonstrating their applicability to large-scale lattice structures.

Shengjun Liu, Tao Liu, Qiang Zou, Weiming Wang, Eugeni L. Doubrovski, and Charlie C.L. Wang

Multi-axis additive manufacturing allows high flexibility in material deposition along dynamically varied directions. The Cartesian motion platforms include three parallel axes and two rotational axes, where singularity on rotational axes poses a critical challenge for ensuring high-quality manufacturing results. The highly nonlinear mapping in singular regions can convert smooth toolpaths into highly discontinuous motion, leading to over-extrusion or under-extrusion in filament-based additive manufacturing. Our method presents a motion planning approach to support the realization of designed toolpaths for multi-axis additive manufacturing, integrating singularity and collision considerations to improve motion and fabrication quality.

Tianyu Zhang, Xiangjia Chen, Guoxin Fang, Yingjun Tian, and Charlie C.L. Wang

This paper introduces a computational pipeline for designing and fabricating 4D garments as knitwear, focusing on comfort during body movement by controlling elasticity distribution. By using single-jersey jacquard (SJJ) with two yarns, we can knit patterns with varying elastic levels. The garment’s elasticity distribution is optimized via physics-based computation and converted into digital knitting machine instructions through graph-based and tiling algorithms. The effectiveness of our approach is validated through simulations and physical specimens.

Zishun Liu, Xingjian Han, Yuchen Zhang, Xiangjia Chen, Yukun Lai, Eugeni L. Doubrovski, Emily Whiting, and Charlie C.L. Wang